Applications

Recrylic® can be used in virtually any acrylic application:

FAQs

Yes. Recrylic looks, works and performs the same as virgin cast acrylic. In the vast majority of cases, it can be used as a more sustainable alternative.

Recrylic is a great option almost anywhere virgin cast acrylic is used. Some examples include:

Retail displays

LED fixtures

Interior and exterior signs2D and 3D artwork

Photo prints

Wall panels

Window frames

ATM and digital screen surrounds

Table and countertops

Architectural + design features

Light guide plates

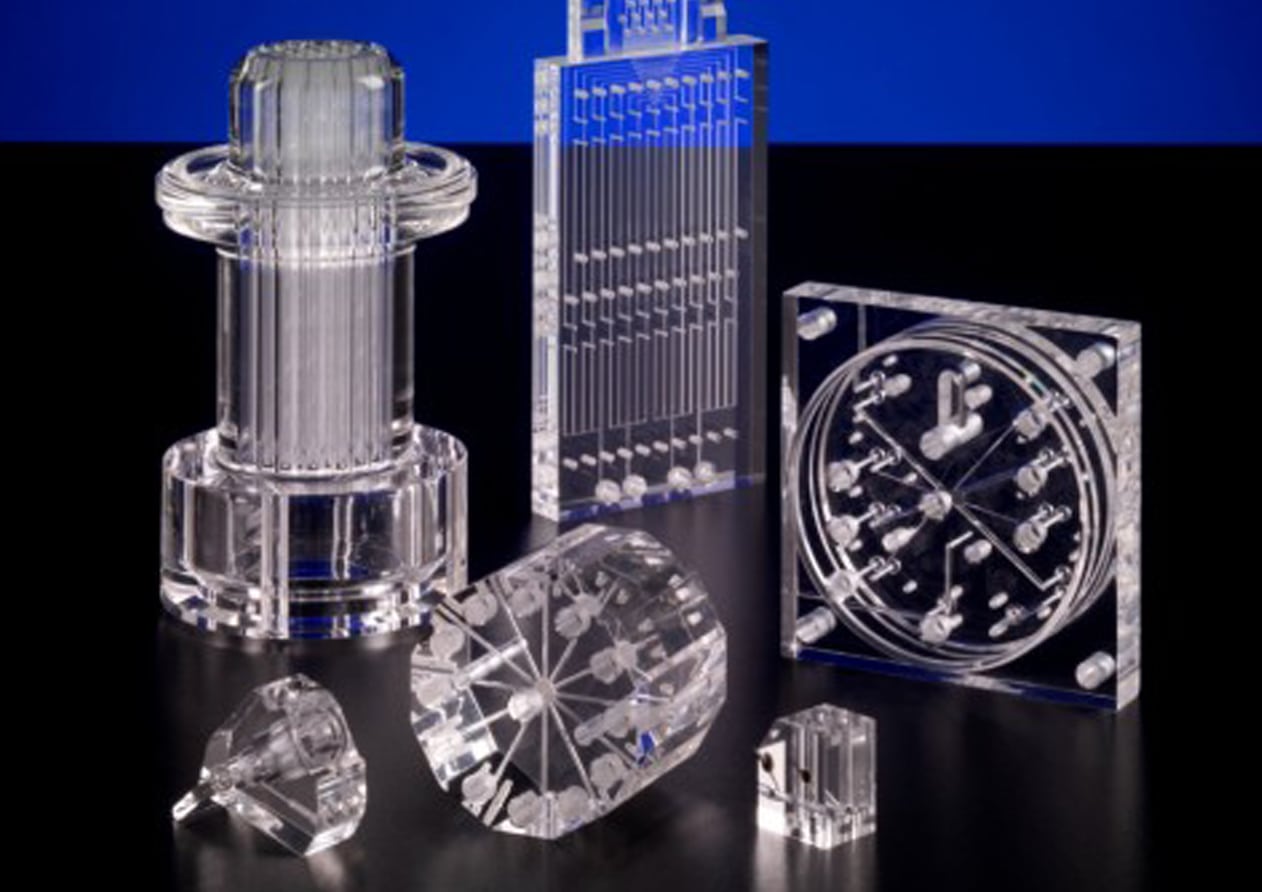

High-precision products

Many more.

There are a few types of specialty acrylic in which Recrylic is not yet available. For example:

Added UV protection. Like any acrylic, Recrylic carries some inherent UV protection. However, some museum displays use acrylic that has specially added UV filters. These are not currently available with Recrylic.

Anti-glare applications. Likewise, Recrylic is not available with anti-glare additives. However, glare can also often be reduced by other methods such as printing or finishing standard Recrylic.

Extruded acrylic applications. Currently, Recrylic is available as cast acrylic only.

Before entering the market, Recrylic was tested extensively to ensure that it looks, works and performs the same as virgin cast acrylic. These tests include (but are not limited to):

CNC, router and saw cutting

Laser etching and cutting

Polishing, sanding and finishing

Heat-forming (drape and vacuum forming)

Printing, paint and lamination

Gluing and joining

Our acrylic fabrication experts tested recycled samples for years in a continuous improvement process to ensure that the end product would meet all needs. Recrylic was introduced only after passing all of these and other tests.

No. As expected from our testing, Recrylic has performed the same as virgin cast acrylic in all respects.

Still have questions?

If your question isn't listed here, we're ready to help! Please fill out the form below, and our team will get back to you promptly.

Contact us

Be the first to know more about Recrylic®.